Manual hydraulic presses offer a versatile solution for various applications, leveraging hydraulic power for controlled force. OpenAI’s ChatGPT, a generative AI,

demonstrates similar innovative capabilities, evolving rapidly since its 2022 release.

These presses, including floor-standing and benchtop models, are valuable in automotive repair and metalworking, mirroring ChatGPT’s broad utility.

ChatGPT’s advancements, like handling 25,000+ words, parallel the increasing sophistication of hydraulic press technology, offering enhanced performance.

What is a Manual Hydraulic Press?

Manual hydraulic presses are mechanical devices utilizing hydraulic force to exert substantial pressure, operated by human power rather than electric or pneumatic systems. They employ a manual pump to generate pressure within a hydraulic cylinder, enabling consistent and controlled force application.

These presses are favored for tasks like bearing installation, metal forming, and manufacturing assembly, offering versatility without the need for complex power infrastructure. Similar to OpenAI’s ChatGPT, a conversational AI, they provide a direct and responsive operational experience.

They are a cost-effective alternative to powered presses, suitable for smaller-scale operations.

Historical Development of Hydraulic Presses

The concept of hydraulic power dates back to ancient times, but the first practical hydraulic press emerged in the 18th century, building upon Pascal’s Law. Early models were large and primarily used in industrial settings.

Manual hydraulic presses evolved as a smaller, more accessible version, gaining prominence in the 20th century for applications like metalworking and automotive repair. This mirrors the development of AI like ChatGPT, starting with basic models and evolving into sophisticated tools.

Continuous refinement has improved their efficiency and usability.

Core Components of a Manual Hydraulic Press

Manual hydraulic presses fundamentally consist of a hydraulic cylinder, a manual pump, and a robust frame. These elements work in concert to generate and apply substantial force.

The hydraulic fluid is also crucial for efficient operation.

The Hydraulic Cylinder

The hydraulic cylinder is the heart of the manual hydraulic press, converting hydraulic pressure into linear mechanical force. It comprises a precision-honed cylinder bore and a tightly-fitting piston.

As hydraulic fluid enters the cylinder, it exerts pressure on the piston, causing it to extend and deliver the pressing force. The cylinder’s diameter directly influences the achievable force output, with larger diameters yielding greater capacity.

Robust construction and tight seals are vital to prevent leaks and maintain consistent performance.

The Manual Pump Mechanism

The manual pump mechanism in a hydraulic press is the operator-driven component responsible for generating the hydraulic pressure. Typically, it involves a lever and piston arrangement within a reservoir of hydraulic fluid.

Repeatedly actuating the lever draws fluid into the pump chamber and then forces it into the hydraulic system, building pressure. The pump’s design dictates the force multiplication ratio and the speed at which pressure is generated.

Efficient pumping action is crucial for consistent operation.

The Frame and Bed Structure

The frame and bed structure of a manual hydraulic press provide the robust foundation necessary to withstand immense forces generated during operation. Constructed from heavy-duty steel, typically welded for rigidity, the frame ensures stability and minimizes deflection under load.

The bed, or platen, serves as the work surface, supporting the workpiece during pressing. Frame design, including throat depth and bed size, dictates the press’s versatility.

Durability is paramount for long-term performance.

Working Principle of a Manual Hydraulic Press

Manual hydraulic presses utilize Pascal’s Law to multiply force via hydraulic fluid. Manual pumping creates pressure, transferring consistent force for metalworking and automotive tasks.

Pascal’s Law and its Application

Pascal’s Law, fundamental to manual hydraulic presses, states pressure applied to a confined fluid is transmitted equally in all directions. This principle enables significant force multiplication.

In a hydraulic press, a small force applied to a small piston generates pressure within the hydraulic fluid. This pressure is then exerted uniformly on a larger piston, resulting in a substantially larger output force.

Essentially, the press trades force for distance, allowing users to achieve immense pressure with manageable manual effort, crucial for tasks like bearing installation.

Force Multiplication Explained

Force multiplication in a manual hydraulic press directly stems from the difference in piston areas. A smaller input piston exerts pressure on the hydraulic fluid, which then acts upon a larger output piston.

The ratio of the output piston area to the input piston area determines the mechanical advantage. For example, if the output piston is ten times larger, the output force will be ten times greater than the input force.

This allows even a relatively small manual effort to generate the substantial force needed for metalworking or automotive repair applications.

The Role of Hydraulic Fluid

Hydraulic fluid is the lifeblood of a manual hydraulic press, transmitting force from the pump to the cylinder. It’s an incompressible medium, ensuring efficient power transfer and responsiveness.

Different fluid types, like mineral oil-based and synthetic options, offer varying properties regarding viscosity, temperature stability, and lubricity.

Maintaining fluid level and preventing leaks are crucial, as compromised fluid impacts performance and can lead to system failure. Some fluids are even flammable, necessitating careful handling.

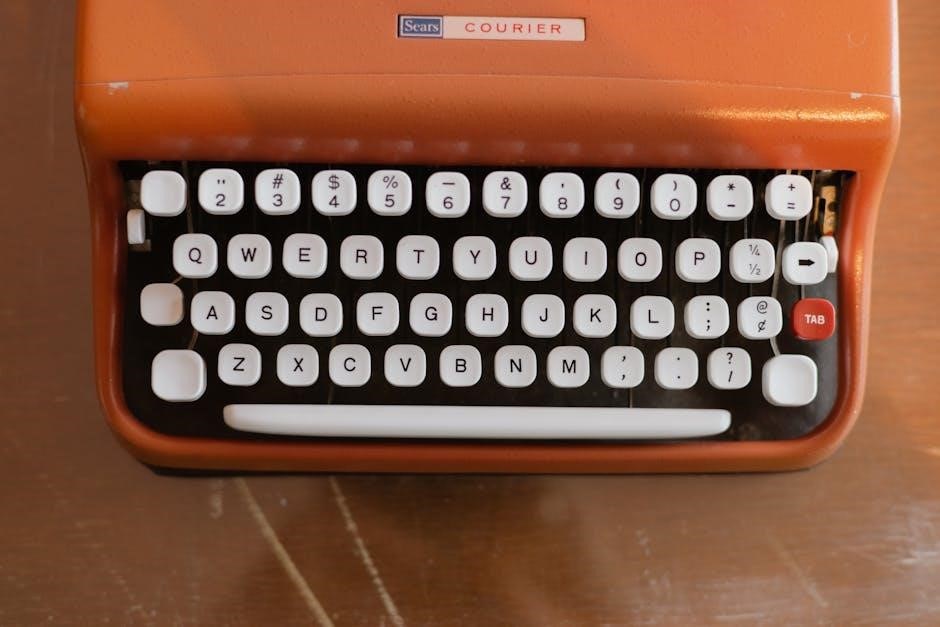

Types of Manual Hydraulic Presses

Manual hydraulic presses come in diverse forms, including benchtop, floor-standing, and arbor presses. These variations cater to different tasks,

like wheel mounting, and offer varying capacities.

Benchtop Hydraulic Presses

Benchtop hydraulic presses are compact, ideal for smaller workspaces and lighter-duty applications. They excel in tasks like hobbyist metalworking, jewelry making, and basic repair work, offering a cost-effective solution.

These presses typically range in capacity from a few tons to 20 tons, providing sufficient force for many common projects. Their portability and ease of setup make them a popular choice for those needing occasional pressing capabilities.

Similar to the versatility of tools like ChatGPT, benchtop presses adapt to diverse needs.

Floor-Standing Hydraulic Presses

Floor-standing hydraulic presses are robust machines designed for heavy-duty applications demanding significant force. Commonly used in automotive shops for bearing installation and removal, they handle tasks beyond the capacity of benchtop models.

These presses typically offer capacities ranging from 20 to 100+ tons, making them suitable for straightening frames, forming thick metal, and other demanding operations. Their stable base ensures safety and precision during use.

Like ChatGPT’s ability to process extensive data, these presses handle substantial workloads.

Arbor Presses (a type of small hydraulic press)

Arbor presses represent a smaller, more precise category within manual hydraulic presses, ideal for lighter-duty tasks. Often utilized for pinning, riveting, and light forming, they offer controlled pressure for delicate work.

Unlike larger floor models, arbor presses prioritize accuracy over sheer force, making them suitable for assembly and intricate metalworking. They are a cost-effective solution for smaller shops or specific applications.

Similar to ChatGPT’s focused responses, arbor presses deliver targeted force.

Applications of Manual Hydraulic Presses

Manual hydraulic presses excel in metalworking, automotive repair (bearing work), and manufacturing. Like ChatGPT’s diverse abilities, they offer broad utility across industries.

These presses mount or unmount wheels, gears, and bearings, showcasing their versatility.

Metalworking and Forming

Manual hydraulic presses are indispensable in metalworking, providing consistent and controlled force for various forming operations. They excel at bending, straightening, crimping, and punching metal sheets and components.

The even pressure distribution, regardless of press size, ensures uniform deformation, crucial for precise results. This capability mirrors the consistent output of advanced AI like ChatGPT, though applied to physical materials.

These presses facilitate the creation of custom parts and prototypes, offering a cost-effective alternative to powered presses for smaller-scale production runs.

Automotive Repair (Bearing Installation/Removal)

Manual hydraulic presses are exceptionally well-suited for automotive repair tasks, particularly the installation and removal of bearings, bushings, and seals. Their controlled force prevents damage to sensitive components during these procedures.

Unlike forceful hammering, a hydraulic press ensures even pressure, minimizing the risk of misalignment or component failure, similar to the precise outputs of AI tools like ChatGPT.

This precision is vital for maintaining vehicle safety and performance, making the press an invaluable asset in any automotive workshop.

Manufacturing and Assembly

Manual hydraulic presses play a crucial role in various manufacturing and assembly processes, offering consistent and repeatable force for tasks like crimping, riveting, and forming. They excel in applications requiring precise pressure control, ensuring product quality and uniformity.

Similar to how ChatGPT generates consistent text outputs, these presses deliver reliable performance, reducing defects and streamlining production workflows.

Their versatility makes them adaptable to diverse assembly needs, contributing to efficient manufacturing operations.

Advantages of Using a Manual Hydraulic Press

Manual hydraulic presses provide consistent force and versatility, offering a cost-effective alternative to powered presses, much like ChatGPT’s accessible AI power.

Consistent and Controlled Force

Manual hydraulic presses excel at delivering remarkably consistent and precisely controlled force throughout the pressing operation. This uniform pressure, regardless of the press’s size, is a key advantage; Unlike inconsistent mechanical methods, hydraulic systems maintain stable output.

This predictability is crucial for tasks demanding precision, such as metalworking and automotive repair, ensuring repeatable results. The operator dictates the force applied, preventing damage to workpieces, mirroring the controlled output of advanced AI like ChatGPT.

Versatility in Applications

Manual hydraulic presses demonstrate exceptional versatility, adapting to a wide spectrum of tasks across diverse industries. From metalworking and forming operations to crucial automotive repair procedures like bearing installation and removal, their adaptability shines.

They are also valuable in manufacturing and assembly processes. Similar to ChatGPT’s ability to handle text, image, and audio analysis, these presses accommodate various workpiece shapes and sizes, making them a truly multipurpose tool.

Cost-Effectiveness Compared to Powered Presses

Manual hydraulic presses present a significantly more cost-effective solution when contrasted with their powered counterparts. The initial investment is considerably lower, eliminating the expenses associated with electric motors, complex control systems, and ongoing energy consumption.

This makes them ideal for smaller workshops or applications where high-volume, continuous operation isn’t required. Like the accessible nature of OpenAI’s ChatGPT, manual presses offer powerful functionality without a prohibitive price tag, maximizing value.

Disadvantages and Limitations

Manual hydraulic presses have limitations, including limited pressure capacity and the need for significant manual effort. Hydraulic fluids can also pose flammability risks, requiring careful handling.

Limited Pressure Capacity

Manual hydraulic presses, unlike their powered counterparts, inherently possess a capped pressure limit. This constraint stems from the physical exertion required to operate the manual pump mechanism. While sufficient for many tasks like bearing installation or simple forming, they struggle with applications demanding extremely high forces.

The regulated pressure prevents tackling heavy-duty metalworking or complex deformation processes. Consequently, users must carefully assess their project requirements to ensure the press’s capacity aligns with the necessary force, avoiding potential damage or inefficiency.

Manual Effort Required

Manual hydraulic presses necessitate significant physical exertion from the operator. The manual pump mechanism demands repetitive pumping action to generate the required hydraulic pressure. This contrasts sharply with powered presses, which automate this process.

Extended use can lead to operator fatigue, potentially impacting consistency and safety. While offering cost-effectiveness, the labor-intensive nature limits continuous operation and may not suit high-volume production environments. Careful consideration of operator stamina is crucial.

Potential for Hydraulic Fluid Leaks

Manual hydraulic presses, relying on hydraulic fluid for operation, are susceptible to leaks over time. Seals, fittings, and hoses can degrade, leading to fluid loss and reduced efficiency. Some hydraulic fluids are even flammable, presenting a safety hazard.

Regular inspection and maintenance are vital to detect and address leaks promptly. Prompt repair prevents contamination, maintains pressure, and minimizes environmental concerns. Choosing appropriate fluid types, like biodegradable options, can mitigate risks.

Safety Considerations When Operating

Manual hydraulic presses demand strict adherence to safety protocols. Personal Protective Equipment (PPE) is crucial, alongside secure workpiece clamping to prevent ejection during operation.

Always avoid exceeding the press’s capacity to prevent damage and potential injury, ensuring a safe working environment.

Personal Protective Equipment (PPE)

Operating a manual hydraulic press necessitates comprehensive Personal Protective Equipment (PPE) to mitigate potential hazards. Safety glasses or a face shield are paramount, protecting eyes from flying debris generated during pressing operations.

Sturdy work gloves enhance grip and shield hands from sharp edges or pinch points. Appropriate footwear, such as steel-toe boots, safeguards against dropped materials. Depending on the application, hearing protection may also be advisable, especially in noisy environments.

Prioritizing PPE ensures operator safety and minimizes the risk of injuries while utilizing this powerful machinery.

Proper Workpiece Securing

Securely fastening the workpiece is crucial when operating a manual hydraulic press, preventing dangerous movement during the pressing process. Utilizing clamps, vises, or custom fixtures ensures stability and accurate alignment.

Always verify the workpiece is firmly held before applying pressure, avoiding potential ejection or shifting that could cause injury or damage. Consider the material and shape when selecting appropriate securing methods.

Improperly secured workpieces can lead to inaccurate results and pose significant safety risks, emphasizing the importance of diligent preparation.

Avoiding Overpressure

Overpressure is a critical safety concern with manual hydraulic presses; exceeding the press’s capacity can cause catastrophic failure, potentially leading to severe injury. Always be aware of the press’s maximum tonnage rating and never attempt to surpass it.

Monitor the pressure gauge closely during operation, and stop pumping once the desired force is achieved. Remember that some hydraulic fluids are flammable, increasing risk.

Consistent and controlled force is key, and exceeding limits compromises both safety and the integrity of the press itself.

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance of your manual hydraulic press. Hydraulic fluid level checks and leak detection are crucial, alongside consistent pump upkeep.

Addressing issues promptly prevents costly repairs and maintains safe operation, mirroring the iterative improvements seen in AI like ChatGPT.

Hydraulic Fluid Level Checks

Regularly inspecting the hydraulic fluid level is paramount for maintaining a manual hydraulic press’s functionality. Locate the reservoir, often with a dipstick or sight glass, and check the fluid level while the press is in a lowered position.

Low fluid levels can introduce air into the system, reducing pressure and efficiency, similar to how insufficient data impacts AI performance like ChatGPT. Top up with the correct fluid type, ensuring cleanliness to prevent contamination, and always follow the manufacturer’s guidelines.

Leak Detection and Repair

Promptly addressing hydraulic fluid leaks is crucial for safe and efficient operation of a manual hydraulic press. Inspect hoses, fittings, and the cylinder for any signs of dampness or drips, much like debugging code in a complex system like ChatGPT.

Tighten loose connections or replace damaged components immediately. Fluid leaks not only reduce pressure but also pose a fire hazard, mirroring the risks of unchecked AI behavior. Always depressurize the system before repairs.

Pump Maintenance

Regular pump maintenance ensures the longevity and optimal performance of your manual hydraulic press. Periodically check the pump handle for smooth operation and listen for unusual noises, similar to monitoring a complex AI like ChatGPT for anomalies.

Clean the pump reservoir and replace the hydraulic fluid according to the manufacturer’s recommendations. Inspect seals for wear and tear, preventing pressure loss and maintaining consistent force.

Choosing the Right Manual Hydraulic Press

Selecting the ideal press requires assessing capacity (tonnage), bed size, and frame durability. Consider your specific needs, like wheel mounting, for optimal performance.

Prioritize robust construction and appropriate dimensions for your intended metalworking or automotive tasks.

Capacity Requirements (Tonnage)

Determining the necessary tonnage is crucial when selecting a manual hydraulic press. This specification dictates the maximum force the press can exert, directly impacting the types of projects it can handle effectively.

For lighter tasks like bearing installation or small metal forming, a lower tonnage press (e.g., 10-20 tons) may suffice. However, more demanding applications, such as straightening larger metal components or pressing heavily reinforced materials, necessitate a higher capacity – potentially 50 tons or more.

Always overestimate your needs slightly to accommodate future projects and ensure the press isn’t consistently operating at its maximum limit, which can reduce its lifespan.

Bed Size and Throat Depth

Bed size and throat depth are critical considerations when choosing a manual hydraulic press. The bed’s surface area dictates the maximum workpiece dimensions the press can accommodate, influencing project versatility.

Throat depth, the distance from the press’s frame to the ram at maximum extension, determines how far into the press you can position and work on a piece. Larger throat depths are essential for handling bulky or awkwardly shaped items.

Carefully assess your typical workpiece sizes to ensure the press’s dimensions align with your operational needs.

Frame Construction and Durability

Frame construction significantly impacts a manual hydraulic press’s longevity and performance. Robust steel frames, often welded, are crucial for withstanding substantial forces generated during operation, ensuring stability and minimizing deflection.

Look for presses with reinforced frames and quality welding to prevent cracking or bending under pressure. A durable frame contributes to consistent force application and overall safety.

Consider the frame’s gauge and design; thicker steel generally indicates greater strength and a longer service life.

Hydraulic Fluid Types and Selection

Hydraulic fluid choices—mineral oil, synthetic, or biodegradable—impact manual hydraulic press performance. Flammability is a concern with some fluids, requiring careful selection for safety;

Proper fluid choice ensures efficient operation and longevity of the press system.

Mineral Oil-Based Fluids

Mineral oil-based hydraulic fluids represent a common and cost-effective choice for manual hydraulic presses. These fluids offer good lubrication and are generally compatible with most seal materials found in standard press designs.

However, it’s crucial to acknowledge a significant drawback: they are flammable, necessitating careful handling and storage to mitigate fire hazards. Additionally, mineral oils exhibit limited biodegradability, posing environmental concerns if leaks occur. Despite these considerations, their affordability and widespread availability continue to make them a popular option for many applications.

Synthetic Hydraulic Fluids

Synthetic hydraulic fluids present a premium alternative for manual hydraulic presses, offering superior performance characteristics compared to mineral oil-based options. These fluids boast enhanced thermal stability, allowing for operation across a wider temperature range without significant viscosity changes.

Furthermore, they exhibit excellent resistance to oxidation and breakdown, extending fluid lifespan and reducing maintenance needs. While generally more expensive upfront, their improved properties and longevity can provide long-term cost savings and enhanced reliability.

Biodegradable Hydraulic Fluids

Biodegradable hydraulic fluids are gaining prominence for manual hydraulic presses, driven by increasing environmental concerns. These fluids, often based on vegetable oils or synthetic esters, minimize ecological impact in case of leaks or spills, offering a greener operational profile.

While typically more costly than mineral oils, their reduced toxicity and faster decomposition rates align with sustainable practices. However, compatibility with press seals and potential for microbial growth require careful consideration.

Future Trends in Hydraulic Press Technology

Manual hydraulic presses are evolving with digital controls and efficient pump designs, mirroring AI advancements like ChatGPT. Advanced materials will enhance durability and performance.

Integration with Digital Controls

Digital control systems are increasingly being integrated into manual hydraulic presses, offering enhanced precision and repeatability previously unattainable. These systems allow for programmed cycles, precise force control, and real-time monitoring of pressure and stroke.

Similar to how OpenAI’s ChatGPT utilizes complex algorithms, digital controls optimize press operation, reducing operator fatigue and minimizing errors. Features like touchscreen interfaces and data logging capabilities further improve efficiency and quality control, mirroring the evolving sophistication of AI-driven technologies.

Development of More Efficient Pump Designs

Innovations in pump technology are crucial for enhancing the performance of manual hydraulic presses. Current research focuses on designs that minimize energy loss and maximize force output with reduced manual effort. These advancements aim to overcome limitations like the limited pressure capacity inherent in manual systems.

Much like OpenAI continually refines ChatGPT’s algorithms for greater efficiency, engineers are exploring new materials and geometries for pumps, striving for smoother operation and increased durability, ultimately boosting the press’s overall effectiveness.

Advanced Materials for Press Construction

Employing advanced materials is transforming manual hydraulic press design, focusing on increased strength and reduced weight. Manufacturers are investigating high-strength alloys and composite materials to build more robust frames and beds, improving durability and stability during operation.

Similar to how OpenAI utilizes powerful computing infrastructure for ChatGPT, these material upgrades enable presses to withstand higher forces and maintain precision, mirroring the AI’s capacity for complex tasks. This leads to longer lifespans and enhanced performance.